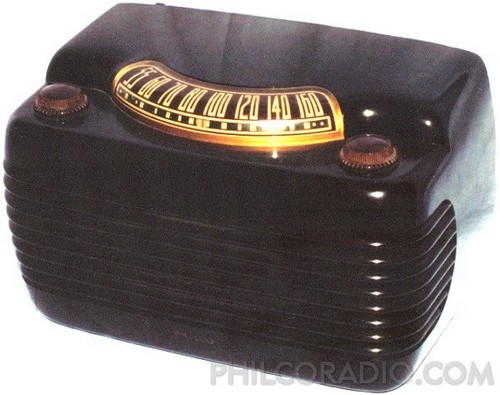

Recently, I took in a beautiful Philco 66B for repair. Manufactured in 1934, this chassis ended up in several different models – a couple of tombstones, a cathedral, and at least two console radios. They’re all 5-tube radios with the AM Broadcast Band and 1 Shortwave band.

![]()

Philco’s designs spanned the entire range of quality, with entry level sets being subject to various interesting design quirks of junior engineers and more advanced sets designed with tight tolerances. They did tend to use potted components longer than most other manufacturers that I’ve worked on, though, and that coupled with quite a few other issues made this one of the most challenging repairs I’ve completed with a lot of unexpected detective work.

![]()

![]()

The tube line-up of 6A7 78 75 42 80 is very common. The 78 tube is effectively identical to the 6D6 tube, although they were developed separately. After testing, this radio needed a new 6A7, 78 and 75 tube which I replaced from my stock. A few spiders once lived inside but were clearly long since gone and were vacuumed out easily.

![]()

Something happened to the speaker at least twice in the past. There’s glue, and two different types of tape applied to the cone.

![]()

The underside looked untouched, or was serviced only at an authorized Philco retailer which replaced with branded components. I couldn’t say for sure.

![]()

This model did have a terminal strip, stacking components in two layers. I had to disconnect a lot of wires to remove it to get at the connections below.

![]()

![]()

![]()

![]()

![]()

![]()

I replaced out of tolerance resistors and capacitors as normal, including the molded bakelite capacitors which I replaced with terminal strips and discrete capacitors. It would have been much easier to work on if Philco had switched to cardboard capacitors for all parts instead of only some.

![]()

![]()

![]()

![]()

![]()

Time for reassembly.

![]()

![]()

The first power-up was a success! In the sense that nothing caught on fire, but it wasn’t making any noise – even when probing various circuit points listening for activity from the speaker. I spent quite a few hours troubleshooting and it turned out to be quite a few very subtle problems which only turned up after a lot of diagnostics. Each resolved problem revealed something new.

![]()

All the coils checked out, and initial checks revealed voltage all the places I expected it.

![]()

As it happened, I accidentally flicked off the power strip with the workbench light instead of the strip with the radio on it, and glanced down in the dark at the tubes to see a bright blue glow in the #42 output tube. That was the first failure. It wasn’t readily visible in the black getter tube under bright lighting, and the tube tested good on the first pass. It must have finally given up during the time it was powered on for troubleshooting. I replaced it with one from stock, and was able to get a few clicks and some minor static, but nothing significant. On a hunch I tested the resistance from various points in circuit to ground, and quite a few had drifted – but the resistors had been replaced! In other cases, the end of a capacitor to ground was several hundred ohms. The 1934 solder joints seemed to have failed. After I tightened down my new grounds and re-soldered others, the resistance was fixed, but it still wasn’t making noise.

I removed a test jumper but noticed I wasn’t getting the right voltages, and it turned out now the #75 detector didn’t have plate voltage. Due to an error on the schematic from the draftsman in 1934, the capacitor’s connection to B+ was omitted.

![]()

In green, I’ve highlighted the path B+ (high voltage) is supposed to flow from the rectifier cathode to the plate of the first audio amplifier. It’s a very straightforward path…if the draftsman had indicated that tube was supposed to be connected to the power supply. In red, I’ve indicated a missing connection symbol. Without it, there was no power being supplied to the first tube in the audio amplifier stage and the audio signal was being killed at that point before it could make it to the final output amplifier. Using an alligator clip, I restored that connection to test, and the radio sprang to life making noise on the next power-up.

The second filter capacitor should have been connected to both B+ and to the plate path for the #75 tube, rather than just the plate path. (Incidentally, the two capacitors are both at the same potential, so under the correct connection scheme could have been replaced with a single capacitor of a larger value.)

With the jumper back in place, the radio powered up and immediately tuned static across the range and it was on to final tweaks. This radio is very susceptible to interference even with the shield in place, but it picked up stations immediately with a 3′ antenna although some were weaker than others. I hooked up my signal generator and oscilloscope.

![]()

The Philco 66 uses a 460 kHz IF, so a nominal frequency of 458.7 kHz is close enough. The signal generator is from the 1950s, and even though it’s been reconditioned, it’s just not very stable – the frequency randomly fluctuated on either side of the center. I’d like to get a synthesized signal generator at some point. This was the same equipment that would’ve been in use at the time (or better), so it’s perfectly suitable for alignment.

![]()

![]()

![]()

Somehow this Philco managed to keep its metal plugs to prevent accidental adjustment to the IF trimmers. I went through the alignment and peaked the dial at the appropriate locations. Then, everything went back together:

![]()

This model of Philco went through quite a few design revisions over its lifetime, which complicated the repair efforts – each variation had slightly different arrangements to defeat interference this model was very vulnerable to. Even perfectly repaired, this radio showed sensitivity even to switching on and off a work lamp near-by and feedback from ambient electronic noise. That’s just the reality of modern electronics life – there wasn’t the same kind of EM spectrum pollution back then there is now, and antique radios often just don’t have the ability to reject interference the way modern electronics do.

Even with the possibility of interference, this Philco came back to life beautifully and tuned across the entire range of AM broadcast stations, perfect for listening to Oldies or the Mariners’ game.

If you’re in the Seattle metro area, I can help bring your antique radio back to life – contact me!

![]()

![]()